MATERIAL CHARACTERIZATION

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanations (Conditions, Exceptions, Tool, etc.) | National / International Standards | TS EN ISO/IEC 17025 Accreditation |

| Dynamic Mechanical Analysis (DMA) Three Point Bending, Single or Dual Cantilever, Tension / Shear / Compression Modes | 30oC - 500oC 30oC - 500oC -150oC - 500oC | ASTM D7028 ASTM D4065 ASTM D4473 | ||

| Flash Differential Scanning Calorimetry (Flash DSC) | 30oC - 550oC | |||

| High Pressure Differential Scanning Calorimetry (HPDSC) | 30oC - 700oC | ASTM D5885 ASTM D5483 ASTM D6186 | ||

| Differential Scanning Calorimetry (DSC) | 30oC - 700oC -60oC - 700oC -150oC - 700oC | ISO 11357-2 | x | |

| ISO 11357-3 | x | |||

| ASTM E793 ASTM E794 | ||||

| DSC Microscopy | 30oC - 700oC -100oC - 500oC | |||

| Oxidation Induction Time / Temperature (OIT) Determination (DSC)

| ISO 11357-6 | |||

| ASTM D3895 | ||||

| Heat Capacity (Cp) Determination (DSC) | 30oC - 500oC | ISO 11357-4 ASTM E1269 | ||

| Thermomechanical Analysis (TMA) | 30oC - 600oC -60oC - 600oC -150oC - 600oC | ASTM E831 ASTM E1545 ASTM E228 | ||

| Thermogravimetric Analysis (TGA / DSC) | 30oC - 1500oC | EN ISO 11358 | x | |

| Determination of Carbon Black (TGA) | ASTM D5805 | |||

| Fourier Transform Infrared Spectroscopy (FTIR) | Spectrum Filming | EN 6042 | ||

| ASTM E1252 | ||||

| High Pressure Liquid Chromatography (HPLC) | Spectrum Filming | EN 6040 | ||

| Thermomechanic HDT / Vicat Test | 30oC - 300oC, HDT | ISO 75, ASTM D648 | ||

| 30oC - 300oC, Vicat | ISO 306, ASTM D1525 | |||

| Thermal Conductivity Measurement | Thermal Conductivity | ISO 22007 | ||

| % Resin, Fiber Determination | Automatic Solvent Extraction | |||

| 24 hour Solvent Extraction | ASTM C613 | |||

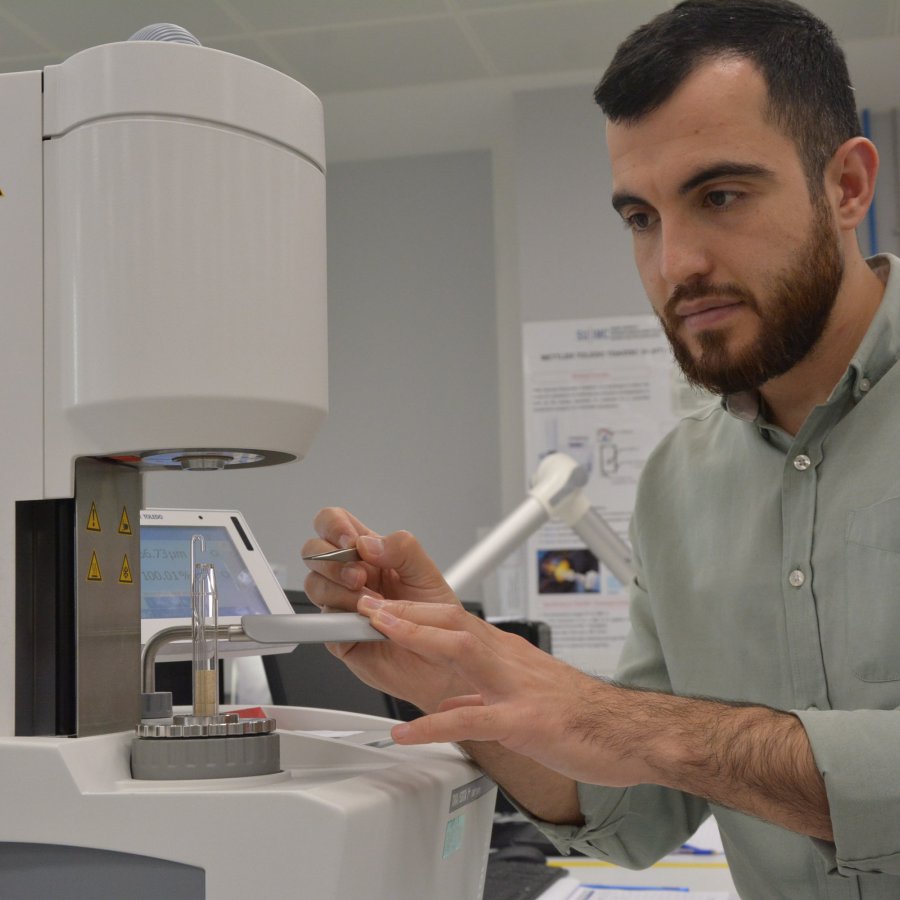

| Surface Tension Measurement | With Wilhelmy Plate | |||

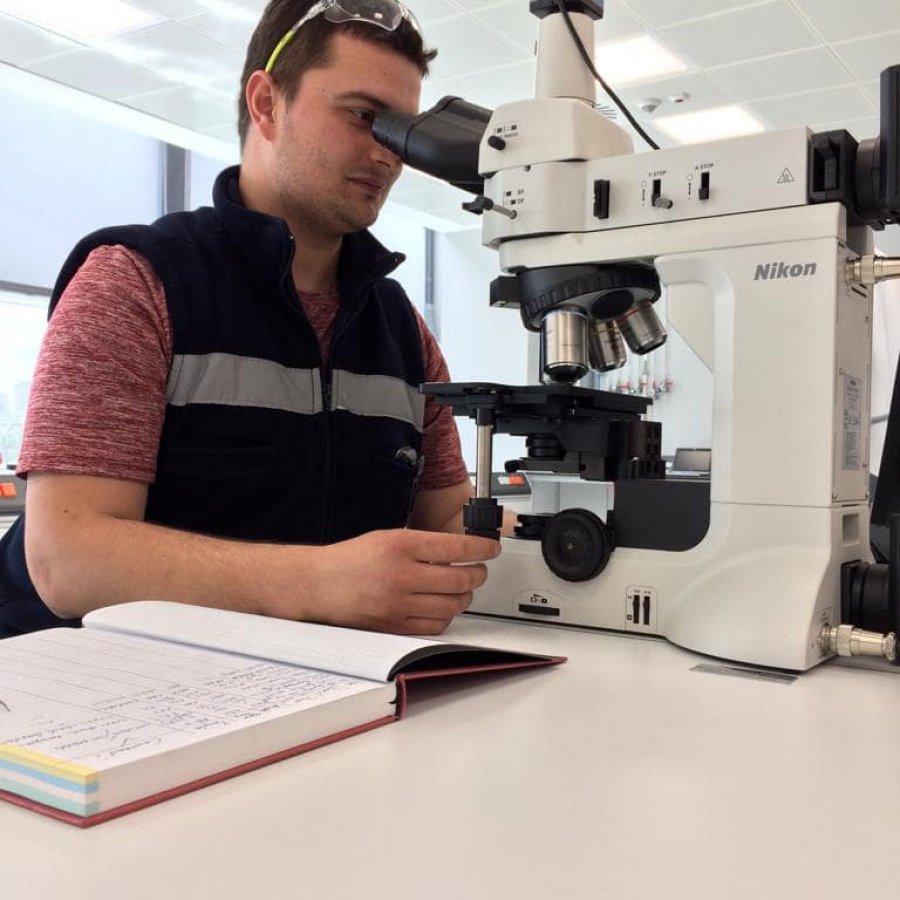

| Microscope Imaging | With Metal or Stereo Optic Microscope | |||

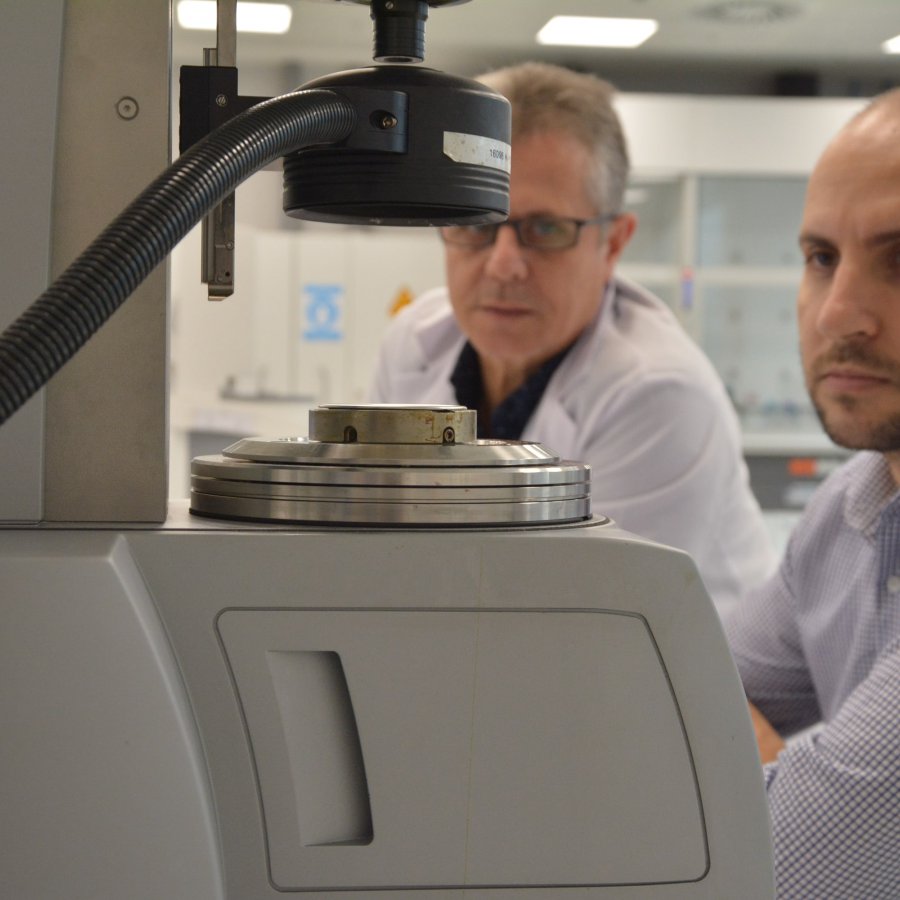

| Temperature Sweep | With Rheometry | ISO 6721-10 | ||

| Strain Sweep | ||||

| Frequency Sweep | ||||

| Viscosity Measurement | ||||

| Determination of Gel Time | ||||

| Thermoplastic Rheology |

A comprehensive characterization of composite materials and their components is crucial in establishing a meaningful structure-property relationship.

In material characterization, we cover the thermal, thermo-mechanical, rheological and structural characterization of all composite materials and individual components used in composite manufacturing.

We can characterize the thermal and thermo-mechanical properties of materials using;

-

Thermo-gravimetric (TGA), differential scanning calorimetry (DSC) and thermal conductivity measurements.

-

In addition to the conventional DSC method, various modes, such as modulated, high pressure and flash DSC can be conducted.

-

Dynamic mechanical analysis (DMA) and thermo-mechanical analysis (TMA) using various test modes for all materials.

-

Rheological analysis, heat deflection temperature (HDT), gel permeation chromatography (GPC), FT-IR spectroscopy, thermal conductivity and contact angle measurement.

OUTPUTS

-

Thermal stability and degradation behavior of materials

-

Thermal transition of materials under controlled, variable heating and cooling rates

-

Thermo-mechanical behavior of materials under load

-

Rheological behavior of materials under variable shear or temperature

-

Thermal conductivity of materials

-

Molecular weight analysis of polymers and oligomers

-

Heat deflection temperature

-

Contact angle of liquids on surfaces

TARGET SECTORS

Aerospace and automotive industries, plastic and polymer processing industries, chemical raw and intermediate material manufacturers.

EQUIPMENTS

-

Fourier Transform Infrared Spectroscopy (FT-IR)

-

Stereo Microscopes

-

Metal Microscopes

-

Differential Scanning Calorimetry (DSC)

-

Simultaneous Thermal Analysis (TGA/DSC)

-

Dynamic Mechanical Analysis (DMA) 40 N

-

Dynamic Mechanical Analysis (DMA) 10 N

-

High Pressure Liquid Chromatography (HPLC)

-

TwinDrive Reometer

-

High-Pressure Differential Scanning Calorimetry (HPDSC)

-

Flash Differential Scanning Calorimetry (Flash DSC)

-

Thermomechanical Analysis (TMA)

-

Analytical Balances

-

Gel Permeation Chromatography (GPC)

-

Liquid Chromatography

-

Thermal Constant Analyzer

-

Automatic Extraction Device

-

HDT / VICAT Test Device

-

Drop Shape Analyzer

-

Tensiometer

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanations (Conditions, Exceptions, Tool, etc.) | National / International Standards | Availability of Laboratory Accreditation / Quality Certification |

| Dynamic Mechanical Analysis (DMA) Three Point Bending, Single or Dual Cantilever, Tension / Shear / Compression Modes | 30oC - 500oC 30oC - 500oC -150oC - 500oC | ASTM D7028 ASTM D4065 ASTM D4473 | ||

| Flash Differential Scanning Calorimetry (Flash DSC) | 30oC - 550oC | |||

| High Pressure Differential Scanning Calorimetry (HPDSC) | 30oC - 700oC | ASTM D5885 ASTM D5483 ASTM D6186 | ||

| Differential Scanning Calorimetry (DSC) | 30oC - 700oC -60oC - 700oC -150oC - 700oC | ISO 11357-2 | x | |

| ISO 11357-3 | x | |||

| ASTM E793 ASTM E794 | ||||

| DSC Microscopy | 30oC - 700oC -100oC - 500oC | |||

| Oxidation Induction Time / Temperature (OIT) Determination (DSC)

| ISO 11357-6 | |||

| ASTM D3895 | ||||

| Heat Capacity (Cp) Determination (DSC) | 30oC - 500oC | ISO 11357-4 ASTM E1269 | ||

| Thermomechanical Analysis (TMA) | 30oC - 600oC -60oC - 600oC -150oC - 600oC | ASTM E831 ASTM E1545 ASTM E228 | ||

| Thermogravimetric Analysis (TGA / DSC) | 30oC - 1500oC | EN ISO 11358 | x | |

| Determination of Carbon Black (TGA) | ASTM D5805 | |||

| Fourier Transform Infrared Spectroscopy (FTIR) | Spectrum Filming | EN 6042 | ||

| ASTM E1252 | ||||

| High Pressure Liquid Chromatography (HPLC) | Spectrum Filming | EN 6040 | ||

| Thermomechanic HDT / Vicat Test | 30oC - 300oC, HDT | ISO 75, ASTM D648 | ||

| 30oC - 300oC, Vicat | ISO 306, ASTM D1525 | |||

| Thermal Conductivity Measurement | Thermal Conductivity | ISO 22007 | ||

| % Resin, Fiber Determination | Automatic Solvent Extraction | |||

| 24 hour Solvent Extraction | ASTM C613 | |||

| Surface Tension Measurement | With Wilhelmy Plate | |||

| Microscope Imaging | With Metal or Stereo Optic Microscope | |||

| Temperature Sweep | With Rheometry | ISO 6721-10 | ||

| Strain Sweep | ||||

| Frequency Sweep | ||||

| Viscosity Measurement | ||||

| Determination of Gel Time | ||||

| Thermoplastic Rheology |