ADDITIVE MANUFACTURING

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanations (Conditions, Exceptions, Tools, etc.) | National / International Standards | Availability of Laboratory Accreditation / Quality Certification |

| Metal Additive Manufacturing | Metal | EOS M290 SLM 250 mm x 250 mm x 325 mm | ||

| Polymer - Composite Additive Manufacturing | Polymer - Fiber(Glass, Carbon, Kevlar) | Markforged Mark One | ||

| Bandsaw Cutting | Metal, Polymer | Kesmak KSY 400 x 600 | ||

| Sandblasting | Metal | Saykar SK1000 | ||

| 3-Axis Milling | Metal, Polymer, Composite | Poysan B5490 540 mm x 900 mm x 200 mm | ||

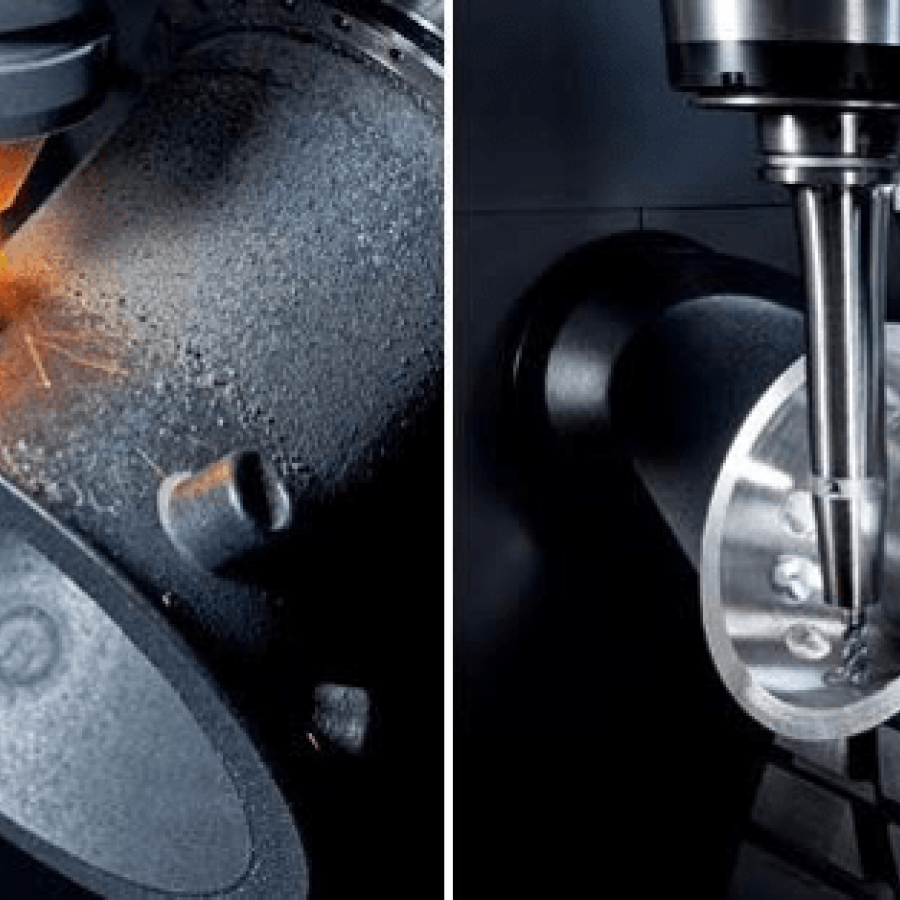

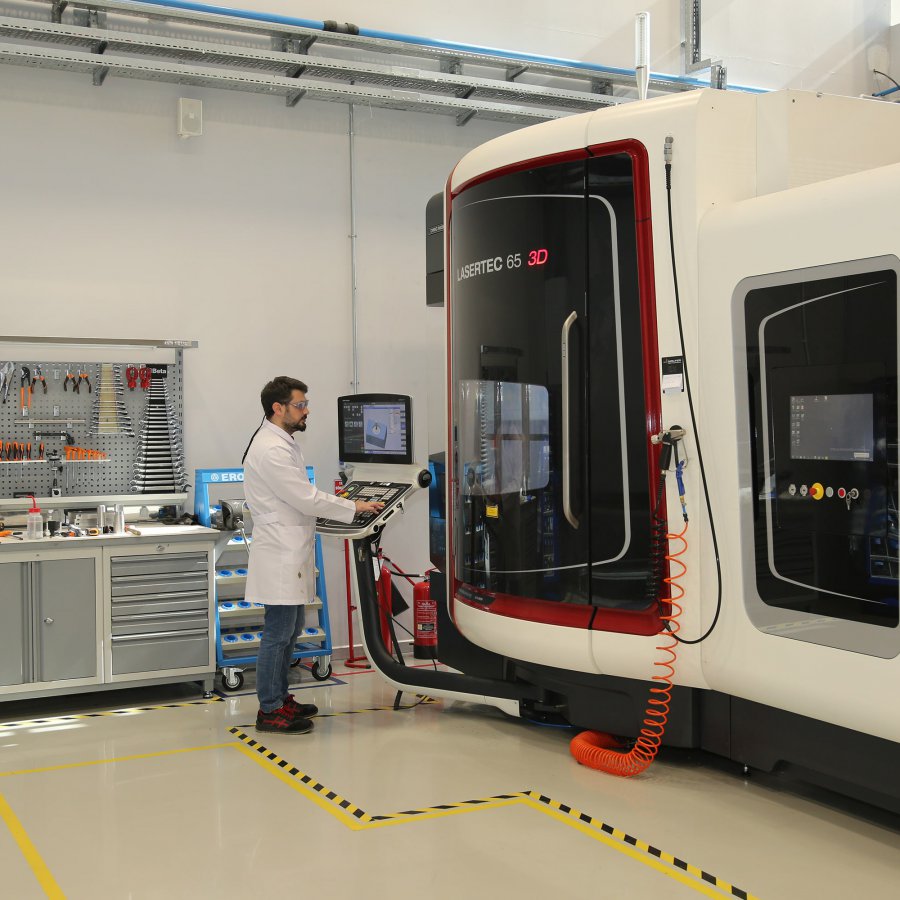

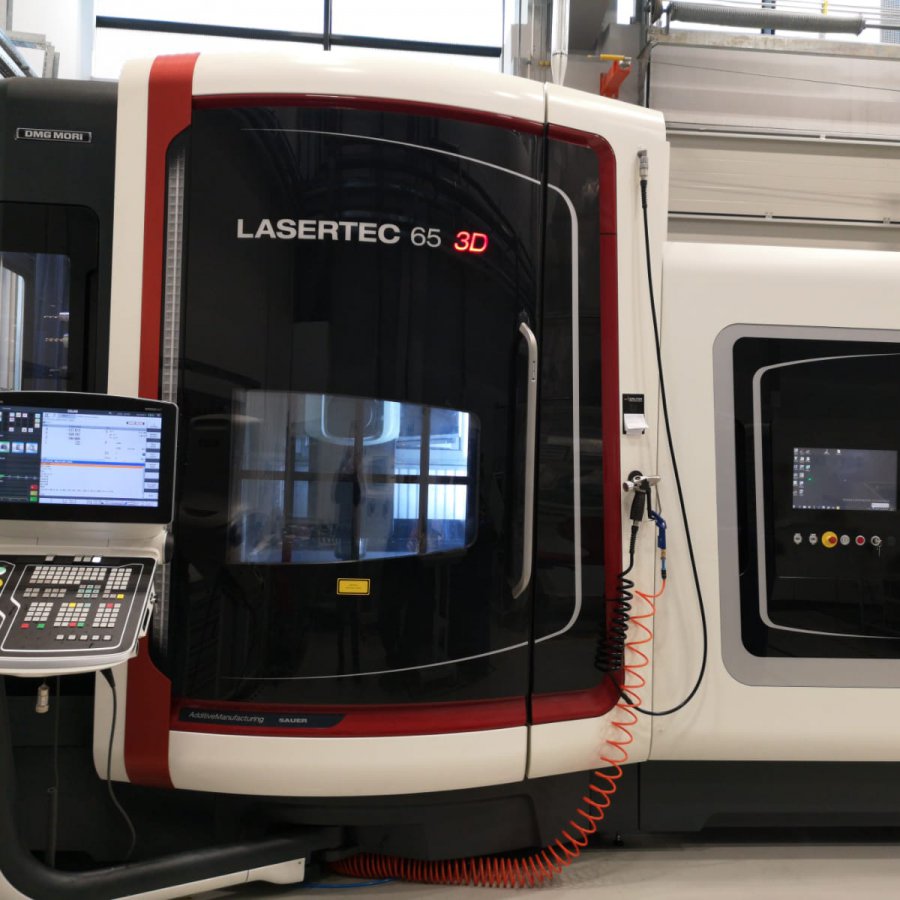

| Hybrid Additive Manufacturing | Metal (Except Ti, Al) | DMG Mori Seiki Lasertec 65 3D 735 mm x 650 mm x 560 mm (3- Axis) Ø650 mm x 560 mm (5-Axis) | ||

| Multi-Axis Milling | Metal | DMG Mori Seiki Lasertec 65 3D 735 mm x 650 mm x 560 mm (3-Axis) Ø650 mm x 560 mm (5-Axis) | ||

| Heat Treatment (with or without Protective Gas Chamber) | Metal | Nabertherm N41H |

Additive Manufacturing is a process of adding materials to manufacture parts layer by layer directly from 3D digital model data, as opposed to subtractive manufacturing methodologies (ASTM F2792). Any complex parts out of plastics, metals, ceramics or composites can be additively manufactured directly from computer models. Therefore, Additive Manufacturing is considered to be the cornerstone of Industry 4.0.

Our focus is on metal, high performance plastic, composite and hybrid Additive Manufacturing processes. We aim to develop novel Additive Manufacturing Technologies by improving and enhancing existing processes as well as developing new hybrid processes for manufacturing multifunctional complex parts.

Our team researches and develops in all the aspects of Additive Manufacturing Technologies from design, path planning and optimization, process development to testing and characterization. We provide solutions for all industries from aerospace, automotive, consumer goods, energy to medical.

We are able to manufacture any complex parts in metal (SS, Nickel, Titanium and Aluminum alloys) and composite materials such as carbon, fiberglass and kevlar composites.

We have the following capabilities:

-

Hybrid process machine which can perform multi-axis milling operations,

-

Multi-axis laser deposition process,

-

Large-area robotic composite/polymer and multi-axis milling system,

-

Post-processing and post-treatment processes such as heat treatment oven, double-column bandsaw and sandblasting cabinets.

-

Saykar Sandblasting SK1000

-

Kesmak KYS 400 x 600 Double Column Bandsaw

OUTPUTS

We aim to develop novel Additive Manufacturing Technologies by improving and enhancing existing processes as well as developing new hybrid processes for manufacturing multifunctional complex parts.

TARGET SECTORS

We provide solutions for all industries from aerospace, automotive, consumer goods, energy to medical.

EQUIPMENTS

-

EOS M290 Selective Laser Melting Machine

-

DMG Mori Seiki Lasertec 65 3D Hybrid Process Machine

-

Custom Robotic Large-Area Composite-Milling Hybrid System

-

Nabertherm Heat Treatment Furnace

-

Saykar Sandblasting SK1000

-

Kesmak KYS 400 x 600 Double Column Bandsaw

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanations (Conditions, Exceptions, Tools, etc.) | National / International Standards | Availability of Laboratory Accreditation / Quality Certification |

| Metal Additive Manufacturing | Metal | EOS M290 SLM 250 mm x 250 mm x 325 mm | ||

| Polymer - Composite Additive Manufacturing | Polymer - Fiber(Glass, Carbon, Kevlar) | Markforged Mark One | ||

| Bandsaw Cutting | Metal, Polymer | Kesmak KSY 400 x 600 | ||

| Sandblasting | Metal | Saykar SK1000 | ||

| 3-Axis Milling | Metal, Polymer, Composite | Poysan B5490 540 mm x 900 mm x 200 mm | ||

| Hybrid Additive Manufacturing | Metal (Except Ti, Al) | DMG Mori Seiki Lasertec 65 3D 735 mm x 650 mm x 560 mm (3- Axis) Ø650 mm x 560 mm (5-Axis) | ||

| Multi-Axis Milling | Metal | DMG Mori Seiki Lasertec 65 3D 735 mm x 650 mm x 560 mm (3-Axis) Ø650 mm x 560 mm (5-Axis) | ||

| Heat Treatment (with or without Protective Gas Chamber) | Metal | Nabertherm N41H |