MECHANICAL TEST AND STRUCTURAL HEALTH MONITORING

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanation (Conditions, Exceptions, Tool, etc) | National / International Standard | TS EN ISO/IEC 17025 Accreditation |

| Tensile Test | Composite | ASTM D3039 | ||

| ASTM D3518 | ||||

| ASTM D5766 | ||||

| EN 2747 | ||||

| EN 2561 | ||||

| EN 2597 | ||||

| EN 6031 | ||||

| ISO 527-5 | ||||

| ISO 14129 | ||||

| Plastics | ISO 527-1 | x | ||

| ISO 527-2 | x | |||

| ISO 527-3 | x | |||

| ISO 527-4 | x | |||

| ASTM D638 | ||||

| Metal | ASTM E8 / E8M | |||

| ISO 6892-1 | x | |||

| Flexure and ILSS Test | Composite and Plastics | ASTM D790 | ||

| ASTM D7264 | ||||

| EN 2562 | ||||

| ISO 14125 | ||||

| EN 2563 | ||||

| ASTM D2344 | ||||

| EN 2377 | ||||

| ISO 178 | ||||

| ISO 14130 | ||||

| Compression Test | Composite and Plastics | ASTM D3410 | ||

| ASTM D6641 | ||||

| ISO 14126 | ||||

| EN 2850 | ||||

| ASTM D6484 | ||||

| ISO 604 | ||||

| ASTM D695 | ||||

| ASTM D1621 | ||||

| Metal | ASTM E9 | |||

| Sandwich and Construction Tests | Core and Facing | ASTM C273 | ||

| ASTM C393 | ||||

| ASTM C365 | ||||

| ASTM C297 | ||||

| ASTM D1781 | ||||

| ASTM D7249 | ||||

| Shear and Peel Tests | Adhesive | ASTM D1002 | ||

| ASTM D3165 | ||||

| ASTM D5868 | ||||

| ASTM D1876 | ||||

| ASTM D1623 | ||||

| ASTM D1876-08 | ||||

| Shear Tests | FRP | ASTM D5379 | ||

| ASTM D7078 | ||||

| Fracture Toughness Tests | Composites | EN 6033 | ||

| EN 6034 | ||||

| ASTM D5528 | ||||

| ASTM D7905 | ||||

| C.A.I and Impact Tests | FRP | EN 6038 | ||

| ASTM D7136 / 7136M | ||||

| Fatigue Tests | FRP | ASTM D3479 | ||

| ISO 13003 | ||||

| Moisture Absorption Tests | FRP | EN 3615 | ||

| ASTM D5229 | ||||

| Pendulum Tests | Plastics and FRP | ISO 179 | ||

| ISO 180 | ||||

| Non Destructive Tests | Thermography | |||

| Acoustic Emission | ||||

| Data Acquisition Units | ||||

| High- Low Temperature Tests | Plastics, FRP and Metals | Between -150 oC and 500 oC | ||

| Strain Measurement System Tests | Clip-On Extansometers | |||

| Video Extansometer | ||||

| Digital Image Correlation System | ||||

| Strain Gauges | ||||

| Fiber Bragg Grating Sensors |

We provide testing services by using our state-of-the-art testing capabilities coupled with experienced professionals in the field.

We can apply a wide range of thermo-mechanical and structural testing standards and requirements with its diverse test set-up and high-end equipment.

We can make high quality, accredited measurements using well-known equipment in the field for their precision and accuracy.

We have the following capabilities:

-

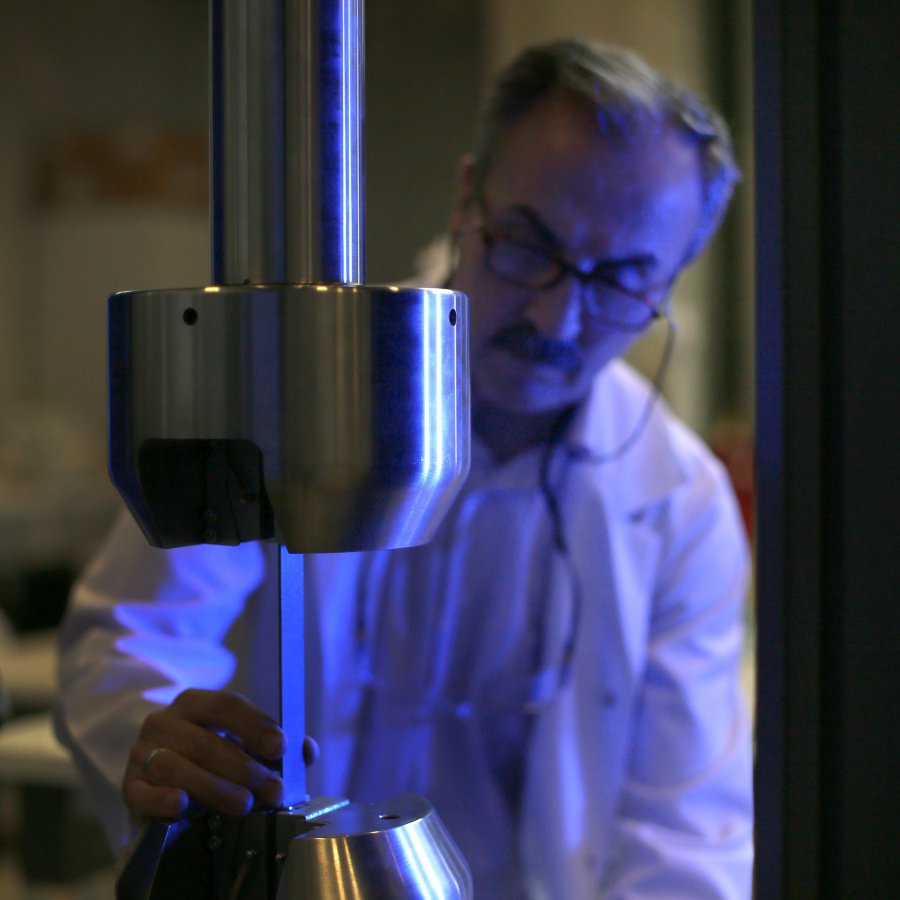

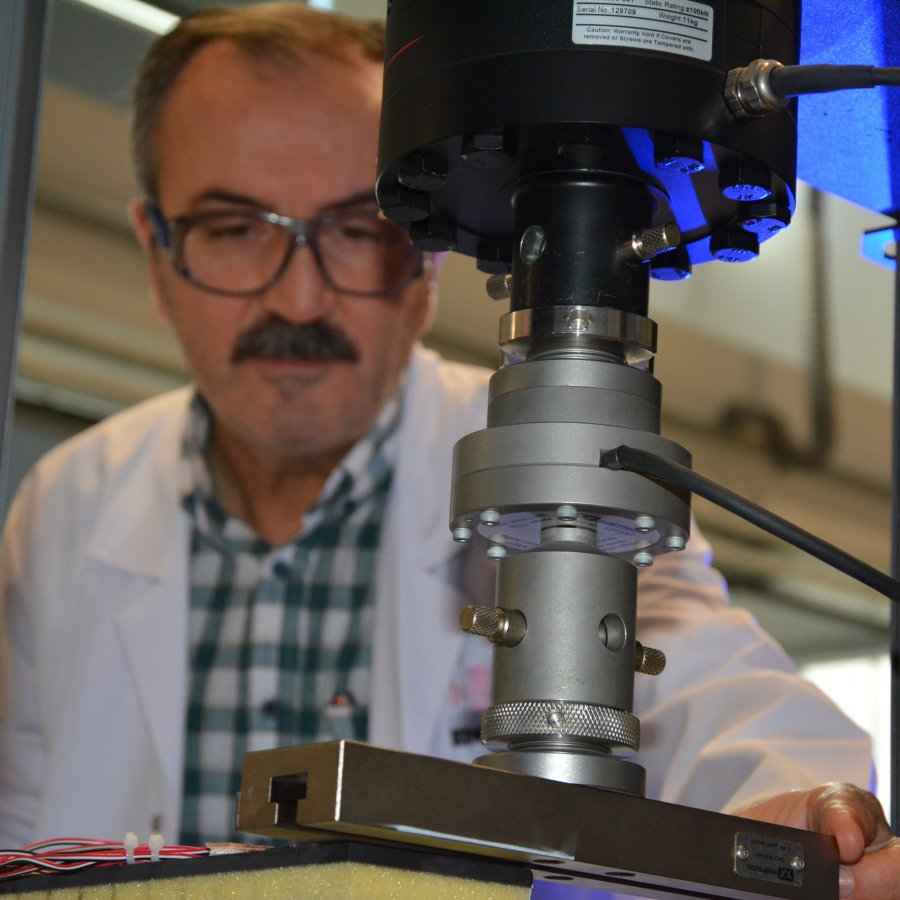

Dynamic and static testing equipment which are recognized for their correctness and performance.

-

Quasi-static and dynamic tests between 0.2 N and 250 kN range can be performed with high accuracy and precision using a variety of extensometers and strain gauges.

-

The tests can be performed at room temperatures and, if desired, at temperatures between -150 ° C and +500 ° C.

-

Non-contact measurement technologies such as high-resolution Digital Image Correlation (DIC), thermography, acoustic emission and Fiber Bragg Grating (FBG) based sensors.

-

High-speed data acquisition, processing and recording systems are utilized during the characterization of composite, plastic and metallic material properties.

-

Drop Tower and Pendulum Impact devices are utilized to perform weight drop or acceleration tests, impact tests on notched or non-notched materials.

-

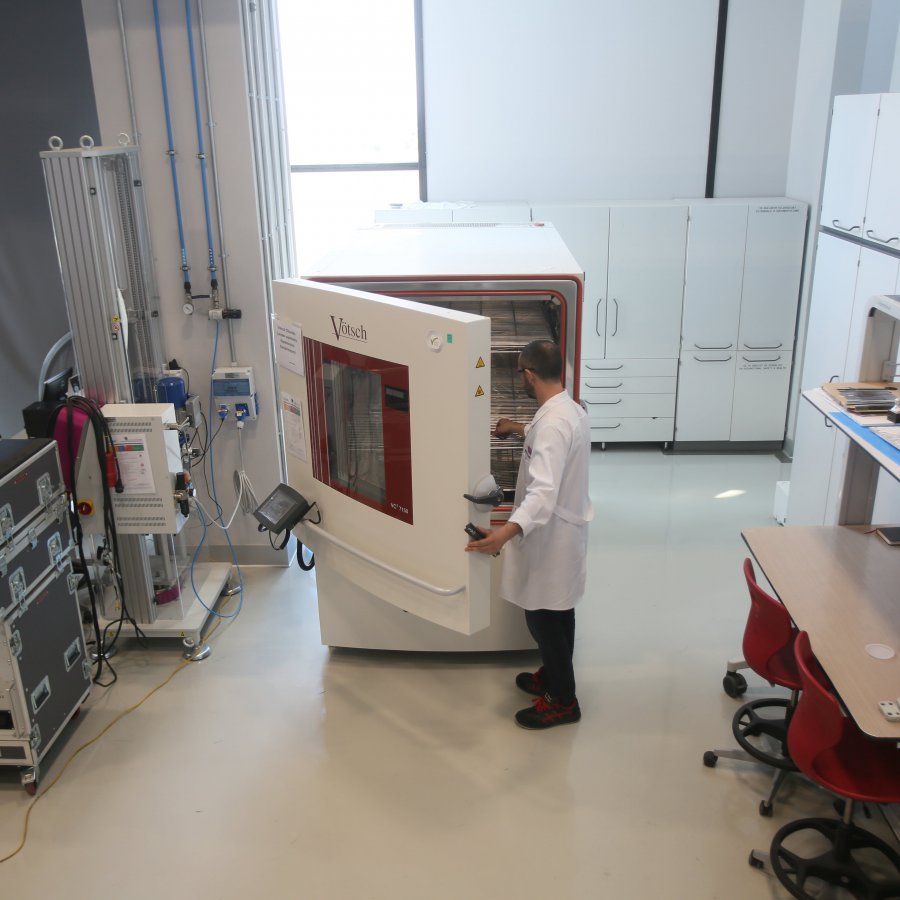

Tests for the ageing and moisture retention capabilities of the materials can be carried out in a highly efficient environment at temperatures between -72 oC and +180 oC, reaching humidity levels between 10% and 98% through the conditioning chamber.

OUTPUTS

-

The mechanical properties of all kinds of materials are characterized and reported per national and international standards,

-

Accredited testing services and reports are provided, all total quality requirements are met and documented.

-

When necessary, new testing techniques for innovative materials are developed and the mechanical behaviour of the materials are characterized.

-

Technical Data Sheets (TDS), Metallic and non-Metallic Materials Properties Development and Standardization (MMPDS) data, Design Allowables (DA), Fatigue and Damage Tolerance (F&DT) characteristics are provided.

-

Characterized material data is provided in accordance with the appropriate input formats to be used in various computational mechanics and simulation software.

TARGET SECTORS

We aim to serve all leading sectors especially aviation, defense, medical, automotive, energy, transportation and advanced materials.

EQUIPMENTS

-

Instron - 100 kN Universal Electromechanical Test Machine

-

Instron - 250 kN, 2kNm Fatigue and Torsion Test Machine

-

Instron - 250 kN Fatigue Test Machine

-

Instron - 100 kN Universal Electromechanical Test Machine

-

Instron - Pendulum Impact Test Machine ( Izod / Charpy )

-

Instron - 450 J Drop Tower

-

Charly 4U Specimen Preparation Machine

-

Vötsch Conditioning Chamber

-

GOM Digital Image Correlation System

-

Micro II Acoustics Emission System

-

Micron Optics FBG Interrogator System

-

Thermography

-

NI High Speed Data Acquisition System

-

Optic Table

| Service Name (Test / Manufacturing Activity) | Sample Material Type | Explanation (Conditions, Exceptions, Tool, etc) | National / International Standard | TS EN ISO/IEC 17025 Accreditation |

| Tensile Test | Composite | ASTM D3039 | ||

| ASTM D3518 | ||||

| ASTM D5766 | ||||

| EN 2747 | ||||

| EN 2561 | ||||

| EN 2597 | ||||

| EN 6031 | ||||

| ISO 527-5 | ||||

| ISO 14129 | ||||

| Plastics | ISO 527-1 | x | ||

| ISO 527-2 | x | |||

| ISO 527-3 | x | |||

| ISO 527-4 | x | |||

| ASTM D638 | ||||

| Metal | ASTM E8 / E8M | |||

| ISO 6892-1 | x | |||

| Flexure and ILSS Test | Composite and Plastics | ASTM D790 | ||

| ASTM D7264 | ||||

| EN 2562 | ||||

| ISO 14125 | ||||

| EN 2563 | ||||

| ASTM D2344 | ||||

| EN 2377 | ||||

| ISO 178 | ||||

| ISO 14130 | ||||

| Compression Test | Composite and Plastics | ASTM D3410 | ||

| ASTM D6641 | ||||

| ISO 14126 | ||||

| EN 2850 | ||||

| ASTM D6484 | ||||

| ISO 604 | ||||

| ASTM D695 | ||||

| ASTM D1621 | ||||

| Metal | ASTM E9 | |||

| Sandwich and Construction Tests | Core and Facing | ASTM C273 | ||

| ASTM C393 | ||||

| ASTM C365 | ||||

| ASTM C297 | ||||

| ASTM D1781 | ||||

| ASTM D7249 | ||||

| Shear and Peel Tests | Adhesive | ASTM D1002 | ||

| ASTM D3165 | ||||

| ASTM D5868 | ||||

| ASTM D1876 | ||||

| ASTM D1623 | ||||

| ASTM D1876-08 | ||||

| Shear Tests | FRP | ASTM D5379 | ||

| ASTM D7078 | ||||

| Fracture Toughness Tests | Composites | EN 6033 | ||

| EN 6034 | ||||

| ASTM D5528 | ||||

| ASTM D7905 | ||||

| C.A.I and Impact Tests | FRP | EN 6038 | ||

| ASTM D7136 / 7136M | ||||

| Fatigue Tests | FRP | ASTM D3479 | ||

| ISO 13003 | ||||

| Moisture Absorption Tests | FRP | EN 3615 | ||

| ASTM D5229 | ||||

| Pendulum Tests | Plastics and FRP | ISO 179 | ||

| ISO 180 | ||||

| Non Destructive Tests | Thermography | |||

| Acoustic Emission | ||||

| Data Acquisition Units | ||||

| High- Low Temperature Tests | Plastics, FRP and Metals | Between -150 oC and 500 oC | ||

| Strain Measurement System Tests | Clip-On Extansometers | |||

| Video Extansometer | ||||

| Digital Image Correlation System | ||||

| Strain Gauges | ||||

| Fiber Bragg Grating Sensors |